Do you need to certify or measure any mechanical property of your plastic material?

Weld properties are often the most important because virtually all service conditions involve some pressure or mechanical load.

Destructive tests

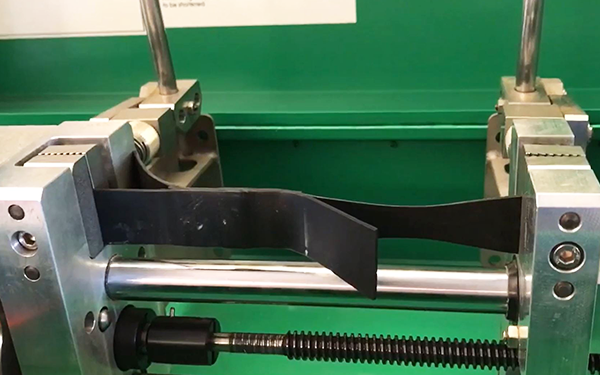

Traction

Bending test

In this case, it is necessary to change the supports and the loading tool. The test consists of subjecting a specimen, supported at the ends, to a force on its perpendicular axis.

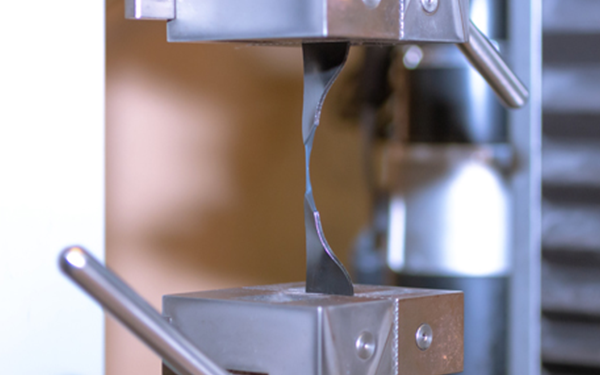

Tear test

The general standards that are usually used are DVS 2207-5. There are other standards that speak of tear tests that apply more to plastic films specifically and that follow standards related to those just mentioned, for example, UNE-EN ISO 6383-2 or UNE-EN 6383-1 and UNE-ISO 34-1 according to the tensile test according to DIN EN ISO 527.

Stripping separation

It is applicable to the study of any type of joint, regardless of the method used to join the materials (heat-sealing, gluing, sewing, multilayer joining, etc.).

Are you interested in this service?

Communicate with our collaborators.

Get more information

Fill your details.